Ferme Park Depot

Ferme Park is part of the IEP Depots framework. At this location in North London, Spencer Rail Engineering completed the enhancement project to facilitate the maintenance of Hitachi Trains’ new fleet of Class 800 and 801 Super Express Trains. This new fleet will run at speeds of up to 125mph and reduce journey times on the East Coast main line (ECML).

Client

Network Rail

Duration

9 months

Location

London

KEY STATISTICS

38,500

Hours Worked

0

Accidents

100%

Of Timber from Recycled/Sustainable Sources

PROJECT SCOPE

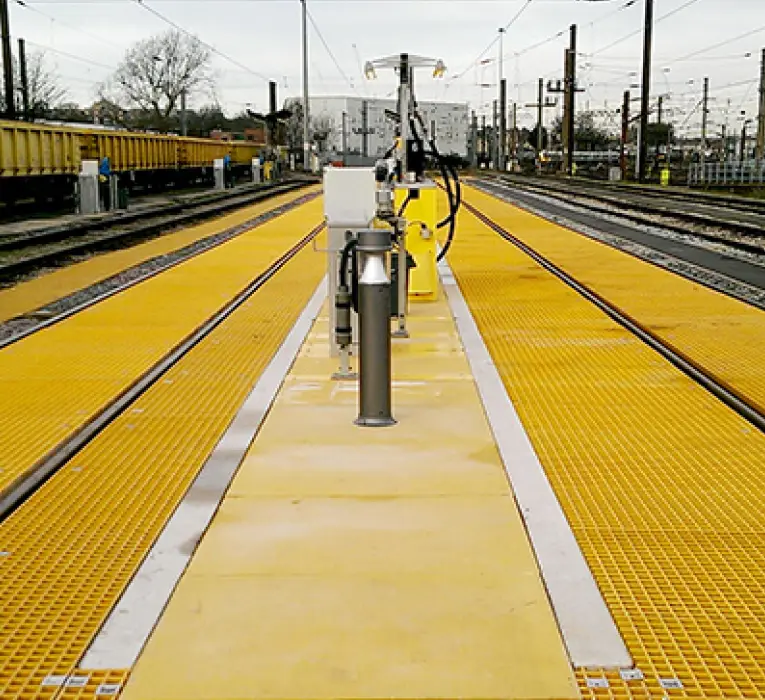

Spencer Rail Engineering was required to install facilities to refuel, clean trains (interior and exterior), empty the controlled emissions toilets and replenish the water tanks of the 5 car or 9 car super trains. AdBlue was installed at each fuel point. Through our multidisciplinary in-house design team, Spencer’s were able to provide a full design and build service, completing the detailed design of all civils and M&E. All disruptive works were completed in time for Spencer’s to start the next phase of disruption at Craigentinny depot – this was significant as any overrun could have had a major delay impact on the whole IEP depots programme.

CAPABILITIES