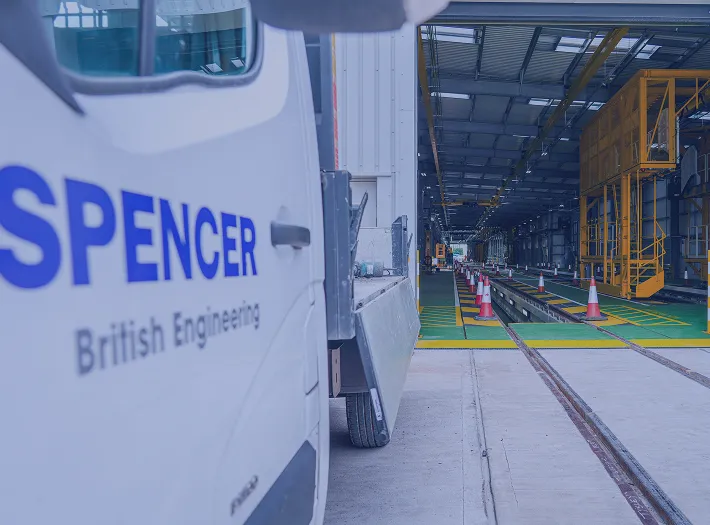

Tyseley Depot Fuel Road Improvements

Spencer Rail Engineering were appointed by West Midlands Trains to upgrade the existing fuel roads at Tyseley Depot. Enabling works included installing a temporary fuelling and CET system to allow disruptive works to take place, one road at a time. The project involved improvements to fuelling roads, including capital plant, maintenance pit extensions/upgrades and the replacement of canopies. Spencer Rail Engineering also provided additional M&E services including coolant, oils, screen wash, mobile sanding, CET, compressed air, lighting, shore supplies, depot protection interlocking, train access gantries, and associated power supplies.

The project scope involved the upgrade to existing fuel Roads 13, 14 and 15 at Tyseley Depot including the installation of temporary fuelling and CET to Road 12. Fuel point improvements – extension and repairs to Roads 14 and 15 rail pits.

Installation of additional piped services for antifreeze (coolant), oils and screen wash. Installation of additional piped services for CET, compressed air and washing lances. System of nose end access at both ends of the Fuel Point Roads.

Drainage improvements to associated areas. Sheet piling to Roads 14 and 15 pit extensions. Access improvements to on-site fuel tanks and mitigation of existing

site issues – removal of walking route trip hazards.

The works also included improvements and extension of 4 cars on Roads 13, 14 and 15. Removal, extension and replacement of the existing Road 14/15 canopy. Removal and replacement of the existing Road 13/14 canopy, leaving skeleton ends.

Provision of mobile sanding bowsers and bowsers for oils and coolant. Installation of associated power supplies and provision of Shore supply x8 16amp sockets.